GRAEFF(格拉夫)工业压力传感器及变送器以其高精度、高可靠性和稳定性,在工业自动化、石油和天然气、化工、水务、电力、暖通空调、食品饮料、汽车、制药、压缩机、注塑机等众多领域得到了广泛的应用。

With its high precision, high reliability and stability, GRAEFF industrial pressure sensors and transmitters have been widely used in many fields such as industrial automation, oil and gas, chemical, water, electricity, HVAC, food and beverage, automotive, pharmaceutical, compressor, injection molding machine and so on.

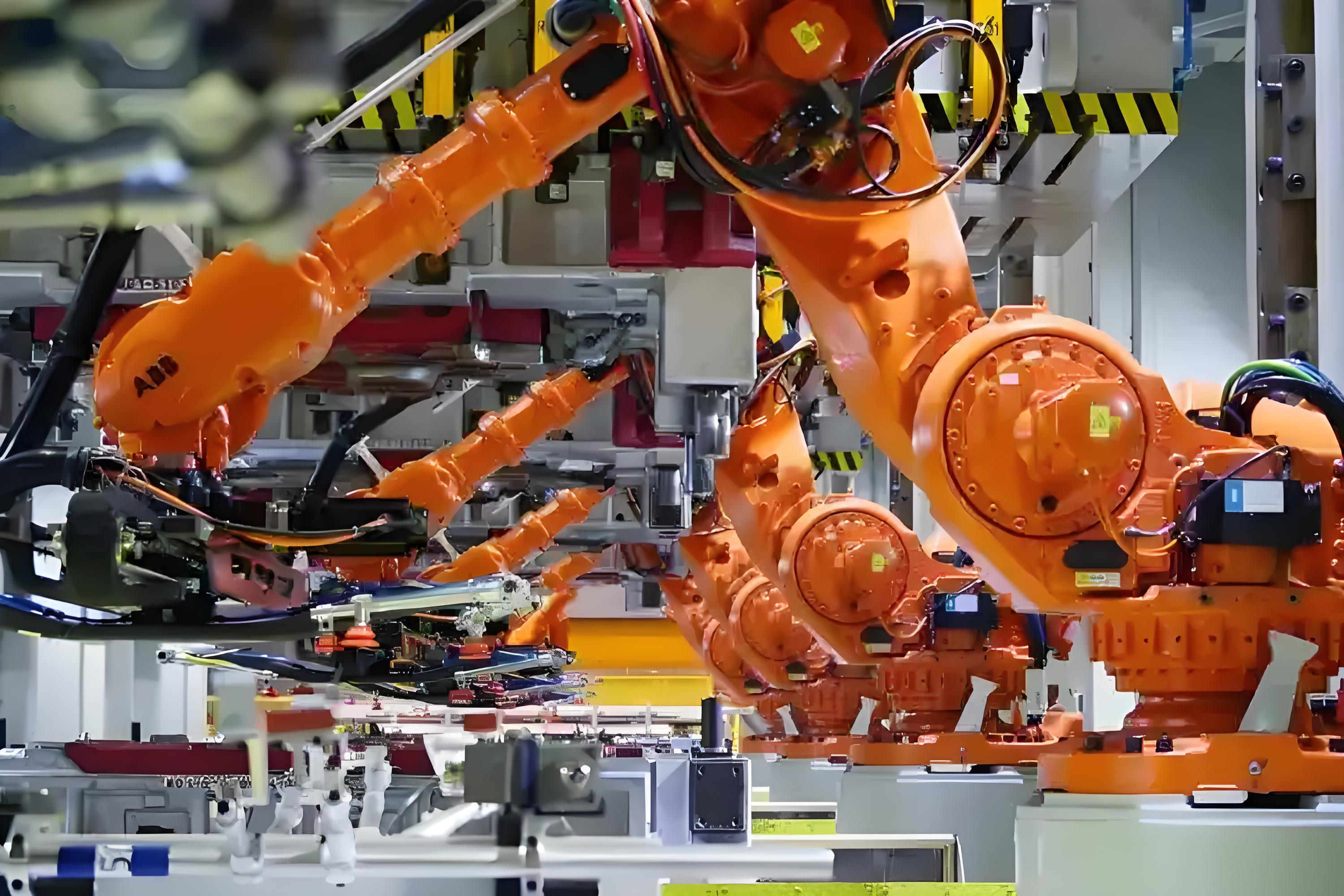

工业自动化领域

在工业自动化生产中,GRAEFF(格拉夫) 压力传感器及变送器扮演着至关重要的角色。它们被广泛应用于各类机械设备的压力监测与控制,如数控机床、自动化生产线等。通过实时监测压力参数,能够及时发现设备运行中的异常情况,从而实现预防性维护,提高设备的运行效率和可靠性。此外,这些传感器还可以与工业自动化控制系统集成,实现对生产过程的精确控制,确保产品质量的稳定性和一致性。

In industrial automation production, GRAEFF pressure sensors and transmitters play a crucial role. They are widely used in various types of mechanical equipment pressure monitoring and control, such as CNC machine tools, automatic production lines, etc. By monitoring the pressure parameters in real time, you can detect the abnormal conditions in the operation of the equipment in time, so as to achieve preventive maintenance and improve the operating efficiency and reliability of the equipment. In addition, these sensors can also be integrated with industrial automation control systems to achieve precise control of the production process and ensure the stability and consistency of product quality.

石油和天然气领域

油气开采:在井口处安装 GRAEFF(格拉夫) 压力传感器,可实时监测井口压力,为油气开采的安全和高效提供保障。同时,井下压力传感器能够帮助工程师了解地层压力情况,优化开采方案。

油气输送:在管道运输过程中,压力传感器用于监测管道内的压力变化,及时发现泄漏等安全隐患,并确保油气的顺利输送。

油气储存:储罐内的压力监测对于保证储存安全至关重要。GRAEFF(格拉夫)压力传感器能够准确测量储罐内的压力,防止超压或负压情况的发生。

Oil and gas production: The GRAEFF pressure sensor is installed at the wellhead to monitor the wellhead pressure in real time, ensuring the safety and efficiency of oil and gas production. At the same time, downhole pressure sensors can help engineers understand formation pressure conditions and optimize production plans.

Oil and gas transportation: In the process of pipeline transportation, pressure sensors are used to monitor the pressure changes in the pipeline, timely detect leaks and other safety hazards, and ensure the smooth transportation of oil and gas.

Oil and gas storage: Pressure monitoring in tanks is essential to ensure safe storage. The GRAEFF pressure sensor accurately measures the pressure inside the tank, preventing overpressure or negative pressure situations.

化工领域

化学反应过程:化工反应釜内的压力是一个关键参数,GRAEFF(格拉夫)压力传感器可以实时监测反应釜内的压力变化,帮助操作人员控制反应条件,确保反应的顺利进行,提高产品质量和收率。

物料输送:在化工物料的输送过程中,压力传感器用于监测管道内的压力,确保物料在合适的压力下流动,避免堵塞和泄漏等问题。

储罐存储:化工储罐内的压力监测有助于防止储罐超压或负压,保障储罐的安全运行。

Chemical reaction process: The pressure in the chemical reactor is a key parameter, and the GRAEFF pressure sensor can monitor the pressure change in the reactor in real time to help the operator control the reaction conditions, ensure the smooth progress of the reaction, and improve product quality and yield.

Material conveying: In the conveying process of chemical materials, pressure sensors are used to monitor the pressure in the pipeline to ensure that the material flows under the appropriate pressure to avoid problems such as blockage and leakage.

Tank storage: Pressure monitoring in chemical storage tanks helps to prevent overpressure or negative pressure of the tank and ensure the safe operation of the tank.

水务领域

供水系统:GRAEFF(格拉夫)压力传感器用于监测供水管道内的水压,确保供水压力稳定,满足用户的用水需求。同时,通过对水压数据的分析,还可以优化供水调度,降低能耗。

污水处理:在污水处理过程中,压力传感器可用于监测沉淀池、过滤器等设备的压力,保证处理工艺的正常运行,提高污水处理效果。

Water supply system: GRAEFF pressure sensor is used to monitor the water pressure in the water supply pipe to ensure that the water supply pressure is stable and meets the water demand of the user. At the same time, through the analysis of water pressure data, the water supply dispatching can be optimized and the energy consumption can be reduced.

Sewage treatment: In the sewage treatment process, the pressure sensor can be used to monitor the pressure of the sedimentation tank, filter and other equipment to ensure the normal operation of the treatment process and improve the sewage treatment effect.

电力领域

发电厂:在锅炉、汽轮机等设备中安装压力传感器,实时监测设备内部的压力参数,保障发电设备的安全运行。此外,压力传感器还可以用于监测蒸汽管道内的压力,确保蒸汽的正常输送。

电力输送:电缆的绝缘性能与内部压力密切相关,GRAEFF(格拉夫)压力传感器可以用于监测电缆内部的压力,及时发现潜在的故障隐患,提高电力输送的可靠性。

Power plant: Install pressure sensors in boilers, steam turbines and other equipment to monitor the pressure parameters inside the equipment in real time to ensure the safe operation of power generation equipment. In addition, the pressure sensor can also be used to monitor the pressure in the steam pipe to ensure the normal delivery of steam.

Power transmission: The insulation performance of the cable is closely related to the internal pressure, and GRAEFF pressure sensors can be used to monitor the pressure inside the cable, timely detection of potential faults, and improve the reliability of power transmission.

暖通空调领域

空调系统:在空调系统中,冷媒的压力是一个重要的参数。GRAEFF(格拉夫) 压力传感器可以准确测量冷媒的压力,确保空调系统的制冷和制热效果。同时,通过对压力数据的分析,还可以优化空调系统的运行参数,降低能耗。

通风系统:通风系统中的风道压力监测对于保证室内空气质量和节能具有重要意义。压力传感器可以实时监测风道内的压力变化,调节风机的运行频率,实现按需通风,降低能耗。

Air conditioning system: In the air conditioning system, the pressure of the refrigerant is an important parameter. The GRAEFF pressure sensor can accurately measure the pressure of the refrigerant to ensure the cooling and heating effect of the air conditioning system. At the same time, through the analysis of pressure data, the operation parameters of the air conditioning system can be optimized to reduce energy consumption.

Ventilation system: Duct pressure monitoring in ventilation system is of great significance to ensure indoor air quality and energy saving. The pressure sensor can monitor the pressure change in the air duct in real time, adjust the operating frequency of the fan, achieve on-demand ventilation, and reduce energy consumption.

食品饮料领域

食品加工:在食品加工过程中,如蒸煮、烘焙、油炸等环节,需要对设备内部的压力进行精确控制。GRAEFF(格拉夫) 压力传感器可以满足这一需求,确保食品加工的质量和安全性。

饮料生产:在饮料灌装过程中,压力传感器用于监测灌装设备内的压力,确保灌装精度和一致性。同时,在饮料发酵过程中,压力传感器也可以用于监测发酵罐内的压力,为发酵过程的控制提供依据。

包装环节:食品和饮料的包装过程中,需要对包装容器内的压力进行监测,以确保包装的密封性和完整性。GRAEFF(格拉夫) 压力传感器可以提供准确的压力测量数据,保障产品的质量。

Food processing: In the process of food processing, such as cooking, baking, frying and other links, it is necessary to accurately control the pressure inside the equipment. GRAEFF pressure sensors can meet this demand, ensuring the quality and safety of food processing.

Beverage production: During the beverage filling process, pressure sensors are used to monitor the pressure inside the filling equipment to ensure filling accuracy and consistency. At the same time, in the process of beverage fermentation, the pressure sensor can also be used to monitor the pressure in the fermenter, which provides a basis for the control of the fermentation process.

Packaging: During the packaging process of food and beverages, the pressure in the packaging container needs to be monitored to ensure the tightness and integrity of the packaging. GRAEFF pressure sensors provide accurate pressure measurement data to ensure product quality.

汽车领域

发动机系统:汽车发动机的油压、进气压力和排气压力等参数对发动机的性能和可靠性有着重要影响。GRAEFF(格拉夫) 压力传感器可以精确测量这些参数,为发动机的优化控制提供依据,提高发动机的燃油经济性和动力性能。

制动系统:制动系统的油压监测是保证汽车制动安全的关键。压力传感器可以实时监测制动系统的油压变化,确保制动系统的正常运行,提高汽车的制动性能。

轮胎压力监测:GRAEFF(格拉夫)压力传感器还可以用于汽车轮胎压力监测系统(TPMS),实时监测轮胎的压力和温度,提高行车安全性和轮胎的使用寿命。

Engine system: Automotive engine oil pressure, intake pressure and exhaust pressure and other parameters have an important impact on the performance and reliability of the engine. The GRAEFF pressure sensor can accurately measure these parameters, providing the basis for the optimal control of the engine, improving the fuel economy and power performance of the engine.

Brake system: The oil pressure monitoring of the brake system is the key to ensure the safety of the automobile brake. The pressure sensor can monitor the oil pressure change of the braking system in real time, ensure the normal operation of the braking system, and improve the braking performance of the vehicle.

Tire pressure monitoring: GRAEFF pressure sensors can also be used in automotive tire pressure monitoring systems (TPMS) to monitor tire pressure and temperature in real time to improve driving safety and tire life.

制药领域

药品生产过程:在制药生产过程中,如发酵、提取、浓缩等环节,需要对设备内部的压力进行严格控制。GRAEFF(格拉夫)压力传感器可以满足制药行业对压力测量的高精度和高可靠性要求,确保药品生产的质量和安全性。

洁净室环境控制:制药行业的洁净室对环境压力有严格的要求,以防止外界污染物进入洁净室。压力传感器可以用于监测洁净室的风压,保证洁净室的正压环境,维持良好的洁净度。

Drug production process: In the pharmaceutical production process, such as fermentation, extraction, concentration and other links, the pressure inside the equipment needs to be strictly controlled. GRAEFF pressure sensors meet the high precision and reliability requirements of the pharmaceutical industry for pressure measurement, ensuring the quality and safety of pharmaceutical production.

Clean room environmental control: Clean rooms in the pharmaceutical industry have strict requirements for environmental pressure to prevent outside contaminants from entering the clean room. The pressure sensor can be used to monitor the wind pressure of the clean room, ensure the positive pressure environment of the clean room, and maintain good cleanliness.

压缩机领域

压缩机运行监测:GRAEFF(格拉夫)压力传感器用于监测压缩机的排气压力和吸气压力,帮助操作人员了解压缩机的运行状态,及时发现故障隐患。通过对压力数据的分析,还可以优化压缩机的运行参数,提高压缩机的效率和可靠性。

压缩空气系统:在压缩空气系统中,压力传感器用于监测管道内的空气压力,确保压缩空气的供应满足设备的需求。同时,压力传感器还可以用于检测泄漏,及时发现并修复泄漏点,降低能源浪费。

Compressor operation monitoring: GRAEFF pressure sensors are used to monitor the exhaust pressure and suction pressure of the compressor, helping the operator to understand the operating status of the compressor and find hidden faults in time. Through the analysis of pressure data, the operation parameters of the compressor can be optimized to improve the efficiency and reliability of the compressor.

Compressed air system: In a compressed air system, pressure sensors are used to monitor the air pressure in the pipe to ensure that the supply of compressed air meets the needs of the equipment. At the same time, the pressure sensor can also be used to detect leaks, find and repair leaks in time, and reduce energy waste.

注塑机领域

注射压力监测:注塑机在注射过程中,需要精确控制注射压力,以确保塑料制品的质量和一致性。GRAEFF(格拉夫) 压力传感器及变送器可以实时监测注射压力,并将压力信号传输给控制系统,控制系统根据压力反馈调整注射速度和压力,以达到最佳的注塑效果。

保压压力控制:在注塑成型的保压阶段,保持适当的压力对于防止塑料制品的收缩和变形非常重要。GRAEFF(格拉夫) 压力传感器可以准确测量保压压力,帮助控制系统维持稳定的保压状态,提高塑料制品的尺寸精度和外观质量。

模具压力监测:模具内部的压力分布对塑料制品的成型质量有很大影响。通过在模具上安装 GRAEFF(格拉夫) 压力传感器,可以监测模具内不同位置的压力变化,为优化模具设计和工艺参数提供依据,从而提高塑料制品的质量和生产效率。

系统压力监控:注塑机的液压系统需要保持稳定的压力,以确保各个动作的正常运行。GRAEFF(格拉夫) 压力变送器可以监测液压系统的压力,当压力出现异常时,及时发出警报并采取相应的措施,避免设备损坏和生产事故的发生。

工艺优化:通过对 GRAEFF(格拉夫) 压力传感器及变送器采集到的压力数据进行分析,制造商可以了解注塑过程中的压力变化规律,从而优化注塑工艺参数,如注射速度、保压时间、冷却时间等,提高生产效率和产品质量,降低生产成本。

Injection pressure monitoring: During the injection process, the injection pressure needs to be precisely controlled to ensure the quality and consistency of plastic products. The GRAEFF pressure sensor and transmitter can monitor the injection pressure in real time and transmit the pressure signal to the control system, which adjusts the injection speed and pressure according to the pressure feedback to achieve the best injection result.

Pressure control: In the pressure holding stage of injection molding, maintaining the appropriate pressure is very important to prevent the shrinkage and deformation of plastic products. The GRAEFF pressure sensor can accurately measure the pressure holding, help the control system maintain a stable pressure holding state, and improve the dimensional accuracy and appearance quality of plastic products.

Mold pressure monitoring: The pressure distribution inside the mold has a great impact on the molding quality of plastic products. By installing the GRAEFF pressure sensor on the mold, the pressure changes at different positions in the mold can be monitored, providing a basis for optimizing the mold design and process parameters, thereby improving the quality and production efficiency of plastic products.

System pressure monitoring: The hydraulic system of the injection molding machine needs to maintain a stable pressure to ensure the normal operation of each action. GRAEFF pressure transmitter can monitor the pressure of the hydraulic system, when the pressure is abnormal, timely alarm and take appropriate measures to avoid equipment damage and production accidents.

Process optimization: Through the analysis of the pressure data collected by GRAEFF pressure sensors and transmitters, manufacturers can understand the pressure change law during the injection process, so as to optimize the injection process parameters, such as injection speed, pressure holding time, cooling time, etc., improve production efficiency and product quality, and reduce production costs.

综上所述,GRAEFF(格拉夫)工业压力传感器及变送器在多个领域的应用,为各行业的生产过程提供了重要的压力测量和控制手段,有助于提高生产效率、保证产品质量、确保生产安全和实现节能减排等目标。

In summary, the application of GRAEFF industrial pressure sensors and transmitters in many fields provides important pressure measurement and control means for the production process of various industries, which helps to improve production efficiency, ensure product quality, ensure production safety and achieve energy saving and emission reduction goals.