GRAEFF melt pressure sensor (transmitter) installation precautions and electrical connection and debugging

熔体压力传感器(变送器)

是一种精确的测量设备,采用高性能核心元件,数模一体电路设计,通过程序实现线性补偿,可获得其高测量精度,只有妥善处理,它们的使用寿命才会更长。在安装传感器(变送器)之前要小心谨慎,以下介绍一些高温熔体压力传感器(变送器)的安装使用注意事项,正确连接调试,以确保无故障的操作。

Melt pressure sensor (transmitter)

Is a kind of accurate measuring equipment, using high-performance core components, digital analog integrated circuit design, through the program to achieve linear compensation, can obtain its high measurement accuracy, only properly handled, their service life will be longer. Be careful before installing the sensor (transmitter). The following describes some precautions for the installation and use of the high temperature melt pressure sensor (transmitter), and the correct connection and debugging to ensure trouble-free operation.ed the core basic parts, key basic materials, advanced basic technology, industrial technology foundation, industrial basic software and other "five foundations".

01 安装方式

安装 Install

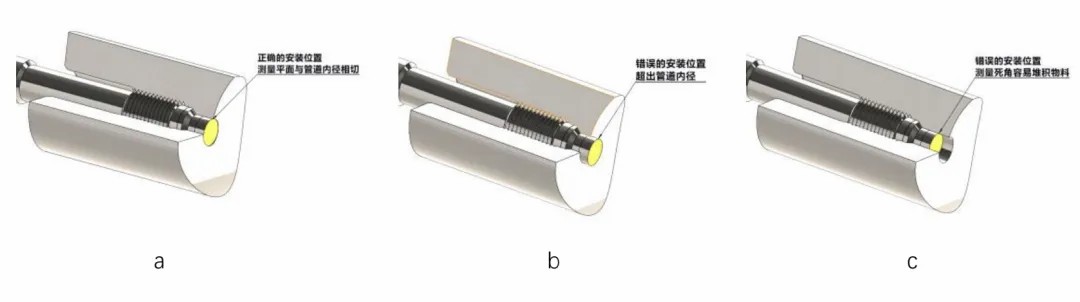

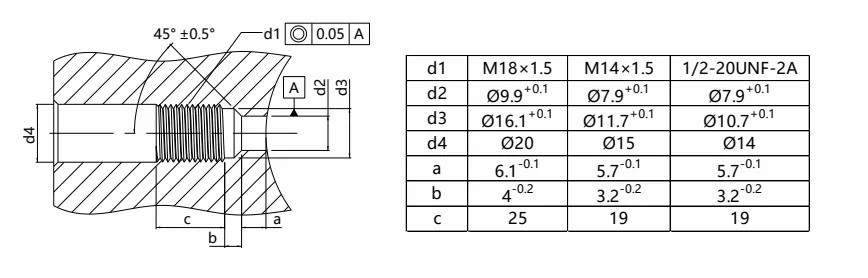

在安装压力传感器(变送器)时,必须注意传感器(变送器)的孔是在下面图纸标注的尺寸要求范围里。装配精度可以通过测试螺栓来检查。图“a”是正确的安装位置,图“b”和“c”都是错误的安装位置,在安装传感器(变送器)之前,首先要清理孔内及螺纹牙之间的杂质,然后在传感器(变送器)螺纹上涂上螺纹防卡油,因不锈钢材质的外螺纹和内螺纹很容易螺牙咬死,涂上螺纹防卡油后可以避免螺牙咬死,在安装传感器(变送器),安装的力量是至关重要的,传感器(变送器)的安装扭矩只能作用在轴上(六边形),不要对传感器(变送器头)部施加任何力。

When installing the pressure sensor (transmitter), it must be noted that the hole of the sensor (transmitter) is within the size requirements indicated in the drawing below. Assembly accuracy can be checked by testing the bolts. Figure "a" is the correct installation position, figure "b" and "c" are the wrong installation position, before installing the sensor (transmitter), first of all to clear the hole and the impurities between the thread teeth, and then in the sensor (transmitter) thread coated with thread anti-stuck oil, because stainless steel external threads and internal threads are easy to die. Coated with thread anti-stuck oil can avoid screw bite, in the installation of the sensor (transmitter), the installation of the force is crucial, the sensor (transmitter) installation torque can only act on the shaft (hexagon), do not apply any force to the sensor (transmitter head) part.

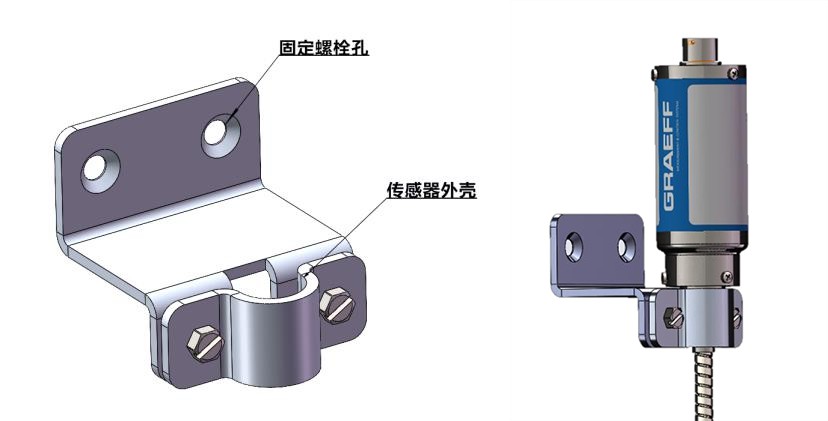

传感器(变送器)的外壳部分需要远离高温区域,采用安装支架将外壳部分固定在支架上(可参照图“D”)。法兰安装方式,根据介质的特性,应在密封面处加上适合的密封垫圈。

1/2-20 UNF /M14×1.5= 最大的启动扭矩:40Nm

M18 x 1.5 =最大的启动扭矩:50 Nm

法兰安装=最大的启动扭矩:50 Nm

The housing part of the sensor (transmitter) should be kept away from the high temperature area, and the housing part should be fixed on the support using the mounting bracket (see figure "D"). Flange installation method, according to the characteristics of the medium, should be in the sealing surface with a suitable sealing gasket.

1/2-20 UNF /M14×1.5= Maximum starting torque: 40Nm

M18 x 1.5 = Maximum starting torque: 50 Nm

Flange mounting = Maximum starting torque: 50 Nm

卸载 Unload

压力传感器(变送器)的拆卸必须在加热的条件下完成(塑料熔化点)。在拆卸传感器(变送器)时,请注意膜片没有接触压力。卸载传感器(变送器)的力必须只施加在轴上(六边形),不要对传感器(变送器)头部施加任何力。

The disassembly of the pressure sensor (transmitter) must be completed under heated conditions (plastic melting point). When removing the sensor (transmitter), note that the diaphragm does not contact pressure. The force to unload the sensor (transmitter) must be applied only to the shaft (hexagon), and no force should be applied to the sensor (transmitter) head.

螺纹安装方式开孔

Threaded mounting holes

02 注意事项

适用范围 Scope of application

熔体压力传感器(变送器)是专为压力监测高温下的液体、气体或糊状物质的产品,它们必须是液态、气态或粘流状态,正常使用下压力不超过测量范围上限,瞬时压力不超过测量范围上限 150% (基于膜片表面)。任何超出上述应用范围的使用不符合规定。

Melt pressure sensors (transmitters) are products designed for pressure monitoring of liquids, gases or pastes at high temperatures, they must be liquid, gaseous or viscous flow states, normal use under pressure does not exceed the upper limit of the measurement range, instantaneous pressure does not exceed 150% of the upper limit of the measurement range (based on the diaphragm surface). Any use outside the above application scope does not comply with the regulations.

危险区域Dangerous area

在熔体压力传感器(变送器)的安装密封区域,如果压力变送器没有被正确安装或卸载,会出现介质泄漏的风险。

In the mounting seal area of the melt pressure sensor (transmitter), there is a risk of media leakage if the pressure transmitter is not properly installed or unloaded.

安全和储存Security and storage

压力传感器(变送器)通常是单独包装,在刚性杆前端螺纹处,感应膜片由保护帽保护,这个保护帽应该在储存的任何时候都要拧紧,只有在使用安装时再打开。

The pressure sensor (transmitter) is usually packaged separately, and at the front thread of the rigid rod, the sensing diaphragm is protected by a protective cap, which should be tightened at any time during storage and only opened when mounting in use.

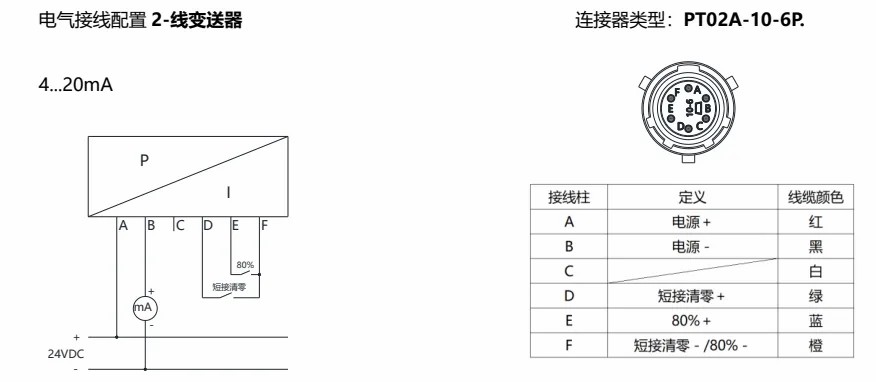

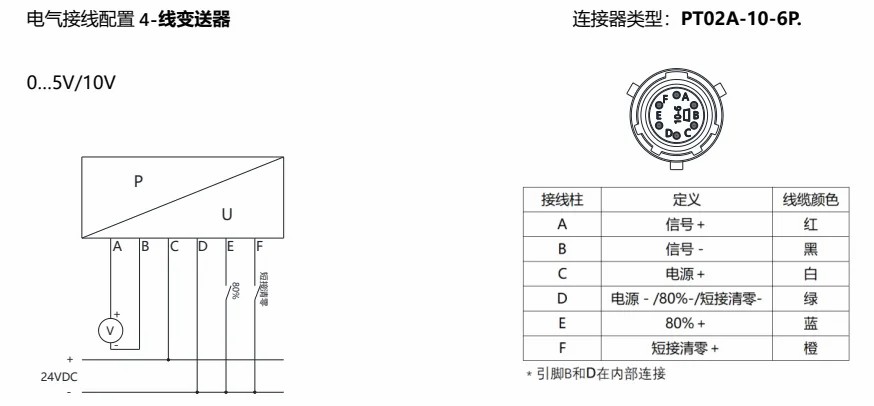

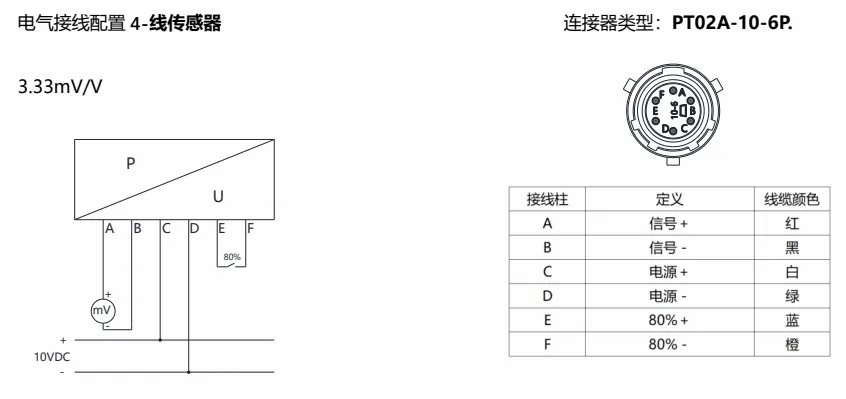

03 调零功能和接线方式

调零功能 Zero function

压力传感器(变送器)已经安装到管线上之后,电气连接必须按照下面接线图所示的连接方式进行。CM 系列压力变送器配有一个集成的放大电路(传感器没有放大电路),清零过程必须是管线被加热且压力为零时进行,零点通过激活自动归零功能调整,自动归零功能是通过相应导线的短连接来启动的(参见接线)。同时也可以采用磁性笔,靠在外壳清零标志处 3-5s 实现清零(参见下图);mV 信号暂无此功能,可以通过后端仪表归零。然后对输出信号进行 80%的检测 (见接线图),压力传感器(变送器)将提供一个标准 80%测量值的信号。

After the pressure sensor (transmitter) has been installed on the line, the electrical connection must be made as shown in the wiring diagram below. The CM series pressure transmitter is equipped with an integrated amplifier circuit (the sensor has no amplifier circuit). The zero clearing process must be carried out when the line is heated and the pressure is zero, which is adjusted by activating the automatic zero function, which is activated by a short connection of the corresponding wire (see wiring). At the same time, you can also use a magnetic pen to clear the shell 3-5s at the zero sign (see the figure below); mV signal does not have this function, can be zero through the back-end instrument. Then 80% of the output signal is detected (see wiring diagram), and the pressure sensor (transmitter) will provide a standard 80% of the measured value signal.

接线方式 Connection mode

变送器系列 :0-10v 4-20mA

Transmitter series: 0-10v 4-20mA

传感器系列 : 3.33mV/V

Sensor series: 3.33mV/V

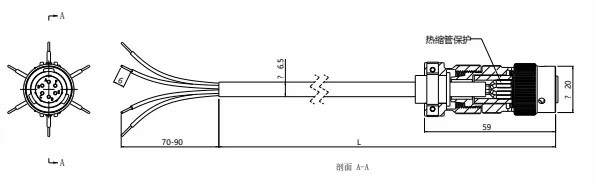

电缆线需采用带屏蔽层电缆,每芯线约 0.3mm2,耐热温度不小于 105℃,每芯线连接接线柱应用热缩管隔离保护,屏蔽线要与插件金属连接,电缆焊接时应特别小心、否则可能会导致信号传输错误或损坏产品、建议使用 GRAEFF 已焊接好的专用电缆线。对电缆线内多余的线,每根线需单独使用绝缘胶带包好。

Cables shall be shielded. Each core wire shall be about 0.3mm2. The heat resistance temperature shall be no less than 105℃. The connecting terminal of each core wire shall be protected by heat shrink tube isolation. Cable welding should be particularly careful, otherwise it may lead to signal transmission errors or damage to the product, it is recommended to use GRAEFF soldered special cable. Use insulation tape to wrap each redundant cable.

4 清理工具使用方式

第一步 The first step

用丝锥清理螺牙之间的塑料,可以来回旋转清理多次,一直到螺纹线里的塑料清理干净。

Clean the plastic between the screws with a tap, and you can rotate it back and forth several times until the plastic in the thread is cleaned up.

第二步 The second step

将铰刀/螺纹套管穿入孔内,再将螺纹套管扭进安装孔内,手指紧就足够了。按顺时针方向旋转铰刀,转 2 圈铰刀,用手指再将螺纹套管拧紧,再按顺时针方向旋转铰刀,重复此动作,直到螺纹套再无推进。

Thread the reamer/threaded bushing into the hole and twist the threaded bushing into the mounting hole. Finger tightness is sufficient. Rotate the reamer clockwise, turn the reamer 2 turns, tighten the threaded casing again with your fingers, then rotate the reamer clockwise, and repeat until there is no further advance in the threaded sleeve.

第三步 The third step

检查孔是否清理正确,可采用丝杆检查,在丝杆膜片外径、端面及 45°密封面位置涂上有颜色的涂液,将丝杆装进孔内拧紧,再拆卸下来,丝杆上应只有 45°密封面位置的涂液被摩擦掉,膜片外径、端面位置的涂液应完整。如果膜片外径、端面位置涂液被摩擦掉,说明没有清理干净,再重复第一步和第二步。

To check whether the hole is cleaned correctly, the screw can be used for inspection. Paint colored coating liquid on the outer diameter, end face and 45° sealing surface of the screw, put the screw into the hole and tighten it, and then remove it. Only the coating liquid at 45° sealing surface of the screw should be rubbed off, and the coating liquid at the outer diameter and end face of the diaphragm should be complete. If the coating liquid is rubbed off the outer diameter and end surface of the diaphragm, it indicates that it has not been cleaned, and then repeat the first and second steps.

其它连接器规格图纸请与工厂联系。

For other connector specifications, please contact the factory.