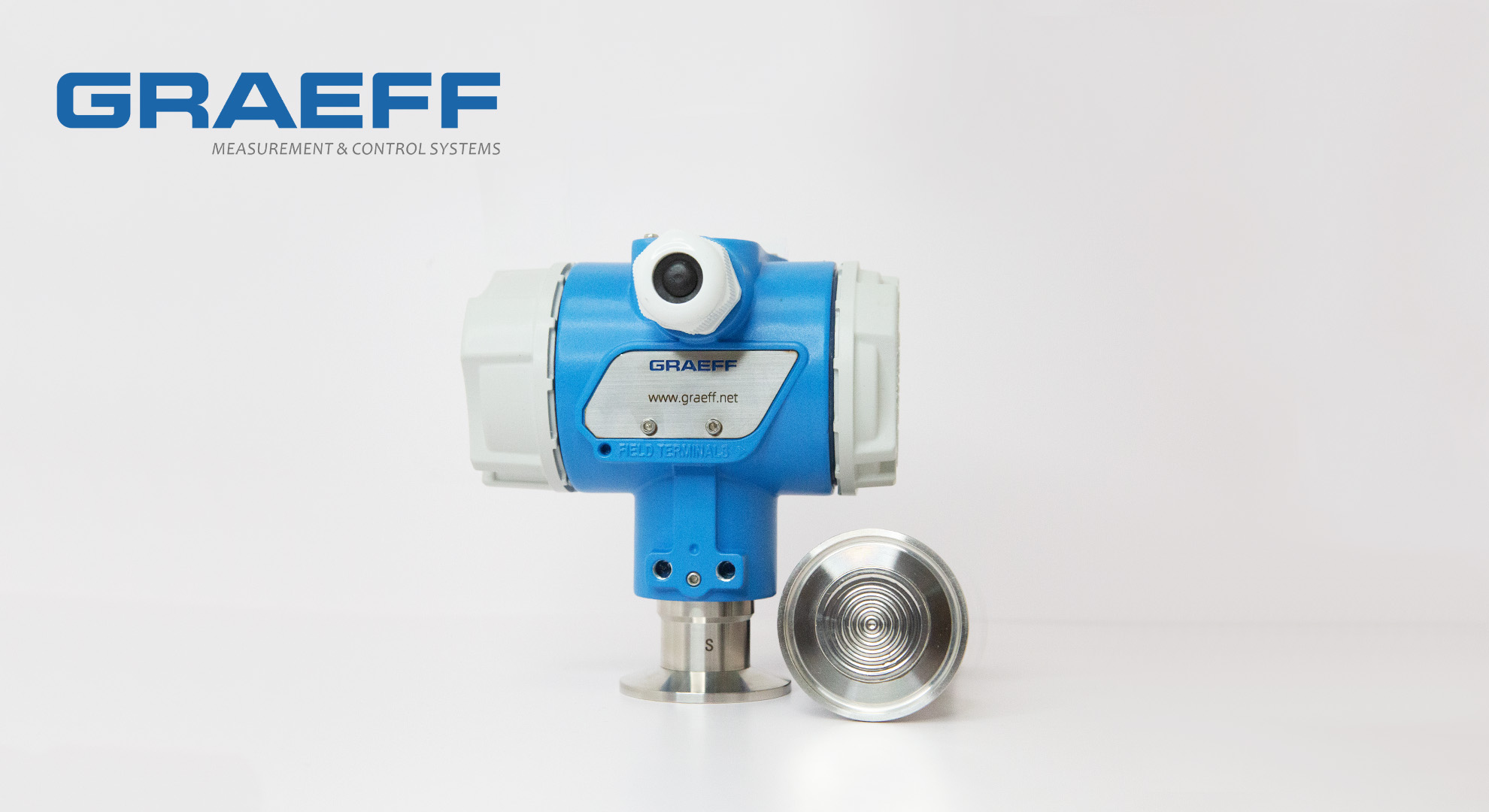

平膜压力传感器的应用

Application of flush diaphragm pressure sensor

平膜压力传感器的工作原理基于介质压力对传感器膜片的作用。当被测介质(气体或液体)对传感器的膜片施加压力时,膜片会产生与介质压力成正比的微位移。这种微位移会导致传感器电阻的变化,进而产生一个与压力相对应的电信号。该电信号经过电子线路的检测和转换后,最终输出一个对应于被测压力的标准信号。

在工业自动化与智能制造的浪潮中,压力传感器作为核心部件,为生产过程的安全、高效与精准提供了关键支持。GRAEFF(格拉夫)平膜压力传感器在化工与石油行业、汽车行业、医疗设备、气象与环境监测、航空航天等领域中都有着广泛的应用

The working principle of the flush diaphragm pressure sensor is based on the effect of medium pressure on the sensor diaphragm. When the measured medium (gas or liquid) exerts pressure on the diaphragm of the sensor, the diaphragm will produce a micro displacement proportional to the pressure of the medium. This micro-displacement causes a change in the resistance of the sensor, which in turn produces an electrical signal corresponding to the pressure. After the electrical signal is detected and converted by the electronic circuit, the final output is a standard signal corresponding to the measured pressure.

In the wave of industrial automation and intelligent manufacturing, pressure sensors, as a core component, provide key support for the safety, efficiency and precision of the production process. GRAEFF flush diaphragm pressure sensors are widely used in the chemical and petroleum industries, the automotive industry, medical equipment, meteorological and environmental monitoring, aerospace and other fields.

1.化工与石油行业

1. Chemical and petroleum industries

管道压力监测:用于监测液体和气体管道系统中的压力变化,确保管道在安全压力范围内运行,防止因超压或低压导致的泄漏、堵塞或设备损坏。

储罐压力测量:实时监测化工原料和成品储罐内的压力,保障储罐的安全运行,同时为生产过程提供准确的压力数据。

反应釜压力监控:在化工反应釜中,传感器用于监测反应过程中的压力变化,确保反应条件的稳定性和安全性。

精馏塔压力控制:用于监测精馏塔内的压力,帮助优化精馏过程,提高分离效率和产品质量。

泵与压缩机进出口压力监测:安装在泵和压缩机的进出口,确保设备在正常压力范围内运行,避免因压力异常导致的设备故障。

安全阀压力检测:监测安全阀的开启压力,确保在超压情况下安全阀能够及时动作,保护系统安全。

腐蚀性介质压力测量:由于其出色的耐腐蚀性,适用于测量强酸、强碱等腐蚀性介质的压力,广泛应用于化工生产中的各种复杂环境。

Pipeline pressure monitoring: Used to monitor pressure changes in liquid and gas piping systems to ensure that the pipeline is operating within a safe pressure range and to prevent leaks, clogging, or equipment damage due to overpressure or low pressure.

Tank pressure measurement: Real-time monitoring of the pressure in chemical raw materials and finished product tanks to ensure the safe operation of the tanks, while providing accurate pressure data for the production process.

Reactor pressure monitoring: In chemical reactors, sensors are used to monitor pressure changes during the reaction process to ensure the stability and safety of reaction conditions.

Distillation column pressure control: Used to monitor the pressure in the distillation column to help optimize the distillation process and improve separation efficiency and product quality.

Pump and compressor inlet and outlet pressure monitoring: Installed at the inlet and outlet of the pump and compressor to ensure that the equipment operates within the normal pressure range to avoid equipment failure caused by abnormal pressure.

Safety valve pressure detection: monitor the opening pressure of the safety valve to ensure that the safety valve can operate in time under overpressure and protect the system.

Corrosive media pressure measurement: Due to its excellent corrosion resistance, it is suitable for measuring the pressure of corrosive media such as strong acid and alkali, and is widely used in various complex environments in chemical production.

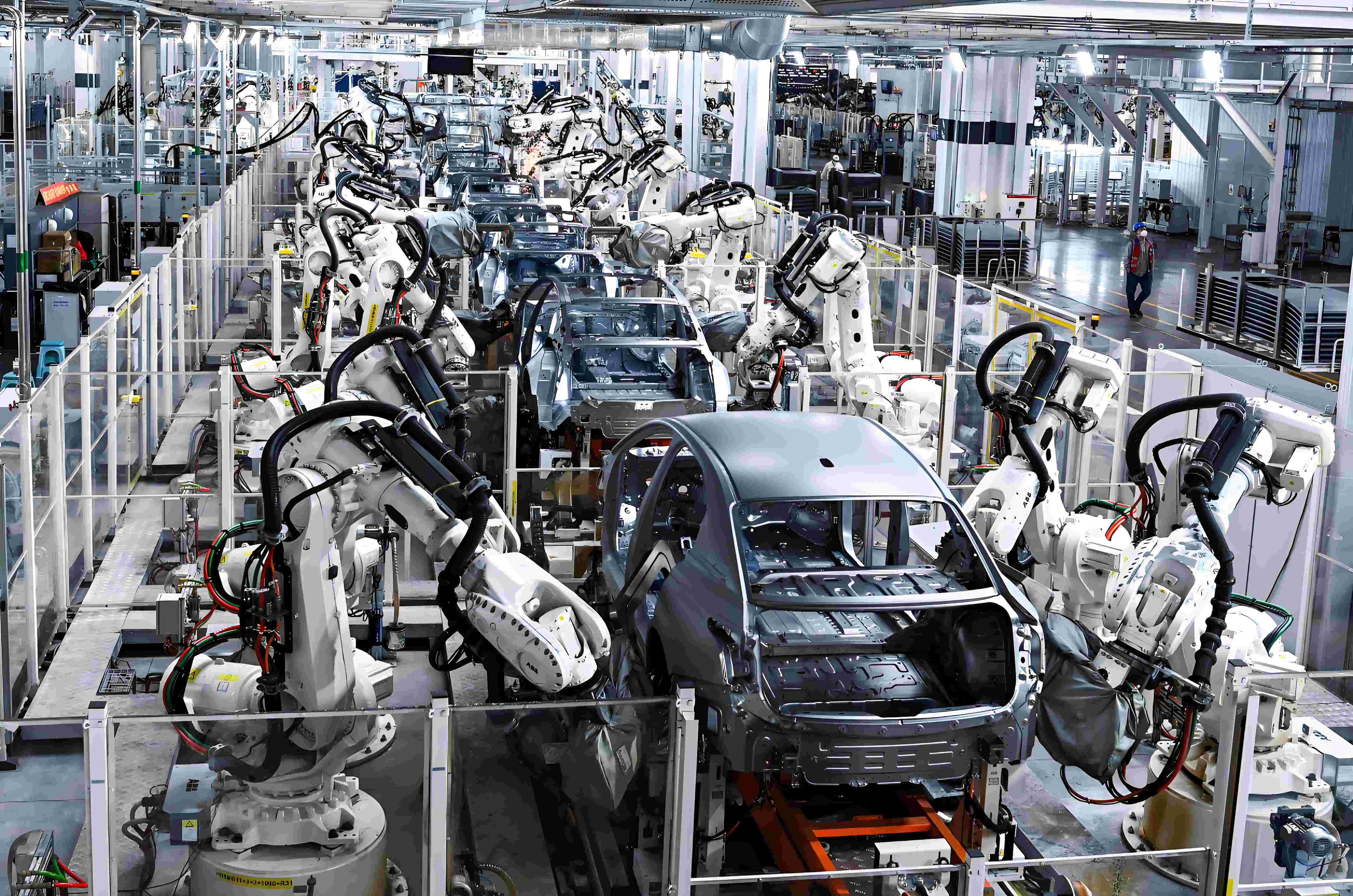

2.汽车行业

2. The automotive industry

发动机进气歧管压力监测:通过测量进气压力,传感器可以为发动机管理系统提供数据,确保发动机在最佳工作状态下运行,从而提高燃油效率和动力性能。

制动液压力监测:实时测量制动系统中的液体压力,确保制动系统的正常工作,提高汽车的安全性能。

悬挂系统压力监测:用于监测悬挂系统中的压力变化,帮助车辆保持稳定的行驶姿态,提升驾驶舒适性。

Engine intake manifold pressure monitoring: By measuring the intake pressure, sensors can provide data to the engine management system to ensure that the engine is operating at its best, thereby improving fuel efficiency and power performance.

Brake fluid pressure monitoring: Real-time measurement of the liquid pressure in the brake system to ensure the normal operation of the brake system and improve the safety performance of the vehicle.

Suspension pressure monitoring: Used to monitor pressure changes in the suspension system to help the vehicle maintain a stable driving posture and improve driving comfort.

3.医疗设备

3. Medical equipment

呼吸机:监测呼吸机内的压力变化,确保患者在使用过程中能够获得稳定的气流支持。

血压计:用于测量血压,提供高精度的压力数据,帮助医生准确诊断病情。

输液泵:监测输液过程中的压力,防止液体回流或堵塞,确保输液过程的安全性和准确性。

血液和体液压力测量:平膜传感器可以直接接触生物介质,测量血液或其他体液的压力,为医疗诊断提供重要依据。

Ventilator: Monitor the pressure changes in the ventilator to ensure that the patient has stable airflow support during use.

Blood Pressure Monitor: Used to measure blood pressure and provide high-precision pressure data to help doctors accurately diagnose the condition.

Infusion pump: Monitor the pressure during infusion, prevent liquid backflow or blockage, and ensure the safety and accuracy of the infusion process.

Blood and body fluid pressure measurement: Flush diaphragm pressure sensor can directly contact biological media to measure the pressure of blood or other body fluids, providing an important basis for medical diagnosis.

4.气象与环境监测

4. Meteorological and environmental monitoring

大气压力监测:通过测量大气压力,为气象预报提供准确的数据支持,帮助预测天气变化。

水压监测:用于监测水质监测系统中的水压,确保系统的正常运行,同时也可以用于地下水位的监测。

风压测量:在一些气象监测设备中,平膜传感器还可以用于测量风压,为风力发电等应用提供数据支持。

Atmospheric pressure monitoring: By measuring atmospheric pressure, it provides accurate data support for meteorological forecasting and helps predict weather changes.

Water pressure monitoring: Used to monitor the water pressure in the water quality monitoring system to ensure the normal operation of the system, but also can be used to monitor the water table.

Wind pressure measurement: In some meteorological monitoring equipment,flush diaphragm pressure sensor can also be used to measure wind pressure, providing data support for applications such as wind power generation.

5.航空航天

5. Aerospace

气瓶压力监测:用于监测飞行器上的氧气瓶、氮气瓶等气瓶的压力,确保气瓶在极端环境下的安全运行。

进气压力监测:在发动机进气系统中,平膜传感器可以测量进气压力,为发动机的正常运行提供保障。

燃料和氧化剂压力监测:在火箭发射和飞行过程中,传感器用于监测燃料和氧化剂的压力,确保火箭的正常发射和飞行。

Cylinder pressure monitoring: used to monitor the pressure of oxygen cylinders, nitrogen cylinders and other cylinders on the aircraft to ensure the safe operation of the cylinders in extreme environments.

Intake pressure monitoring: In the engine intake system, the flush diaphragm pressure sensor can measure the intake pressure to provide guarantee for the normal operation of the engine.

Fuel and oxidizer pressure monitoring: During rocket launch and flight, sensors are used to monitor the pressure of fuel and oxidizer to ensure the normal launch and flight of the rocket.

6.结语

6. Conclusion

GRAEFF(格拉夫)平膜压力传感器以其高精度、高可靠性和出色的抗腐蚀性,为工业生产保驾护航,助力各行业实现智能化升级。成为了工业生产中不可或缺的重要工具。在未来,随着工业技术的不断发展,GRAEFF(格拉夫)平膜压力传感器将继续以其创新的技术和可靠的质量,助力各行业的智能化和高效化发展,为工业生产的每一个环节保驾护航。

With its high precision, high reliability and excellent corrosion resistance, GRAEFF flush diaphragm pressure sensors escort industrial production and help various industries achieve intelligent upgrades. It has become an indispensable tool in industrial production. In the future, with the continuous development of industrial technology, GRAEFF flush diaphragm pressure sensors will continue to help the intelligent and efficient development of various industries with its innovative technology and reliable quality, and escort every link of industrial production.