在工业自动化领域,变送器作为核心测量设备,其性能和选型直接关系到生产过程的精准度、稳定性和效率。GRAEFF(格拉夫)作为浙江嘉兴的高端传感器制造商,凭借其先进的技术和丰富的产品线,为各类工业场景提供高性能的变送器解决方案。以下将从被测介质特性、工况环境、精度要求、安装维护等关键维度,为您深度剖析GRAEFF(格拉夫)变送器的选型要点。

In the field of industrial automation, the transmitter is the core measurement equipment, and its performance and selection are directly related to the accuracy, stability and efficiency of the production process. As a high-end sensor manufacturer based in Jiaxing, Zhejiang Province, GRAEFF provides high-performance transmitter solutions for various industrial scenarios with its advanced technology and rich product lines. The following will be from the characteristics of the tested medium, working environment, accuracy requirements, installation and maintenance and other key dimensions, for you to in-depth analysis of the key points of GRAEFF transmitter selection.

一、被测介质特性

1. Characteristics of the measured medium

了解被测介质的特性是变送器选型的基础,介质的化学性质、温度、压力和腐蚀性等因素将直接影响变送器的性能和寿命。

1. 腐蚀性介质

面对强酸、强碱或腐蚀性介质,GRAEFF(格拉夫)变送器提供多种耐腐蚀材料选择。例如,哈氏合金膜片适用于大多数酸性环境,而钛合金膜片则能有效抵抗多种复杂介质的腐蚀,但需注意避免在氢氟酸环境中使用。

2. 高温介质

在高温工况下(如200℃~400℃),变送器的膜片和填充液需具备耐高温性能。GRAEFF(格拉夫)的高温型变送器采用特种材料和设计,能够有效防止因高温导致的测量误差,确保设备在炼油、化工等高温场景中长期稳定运行。

3. 特殊介质

对于含氢气、易燃易爆或高粘度介质,GRAEFF(格拉夫)提供定制化解决方案。例如,镀金膜片可有效避免氢脆现象,而针对高粘度介质,其变送器采用特殊设计,防止膜片堵塞,确保测量精度。

Understanding the characteristics of the measured medium is the basis of transmitter selection, the chemical properties of the medium, temperature, pressure and corrosion and other factors will directly affect the performance and life of the transmitter.

1. Corrosive media

For strong acids, alkalis or corrosive media, GRAEFF transmitters offer a wide choice of corrosion-resistant materials. For example, Hastelloy films are suitable for most acidic environments, while titanium alloy films can effectively resist the corrosion of a variety of complex media, but care should be taken to avoid use in hydrofluoric acid environments.

2. High temperature media

Under high temperature conditions (such as 200 ° C to 400 ° C), the diaphragm and filling liquid of the transmitter need to have high temperature resistance. GRAEFF's high temperature transmitters use special materials and designs to effectively prevent measurement errors caused by high temperatures and ensure long-term stable operation of equipment in high temperature scenarios such as oil refining and chemical industry.

3. Special media

For hydrogen, flammable and explosive media or high viscosity media, GRAEFF offers customized solutions. For example, the gold-plated diaphragm can effectively avoid hydrogen embrittling, and for high-viscosity media, the transmitter is specially designed to prevent diaphragm clogging and ensure measurement accuracy.

二、工况环境考量

2.working conditions and environmental considerations

工业现场环境复杂多变,变送器的选型需充分考虑环境因素,以确保设备的可靠性和稳定性。

1. 温度范围

除被测介质温度外,环境温度对变送器的影响同样不可忽视。GRAEFF(格拉夫)变送器具备宽广的工作温度范围,并配备温度补偿功能,确保在极端温度条件下仍能保持高精度测量。

2. 压力范围

根据实际工况,选择合适量程的变送器至关重要。GRAEFF(格拉夫)提供从低压到高压的全系列变送器,确保设备量程能够覆盖实际测量压力范围,并预留一定裕量,以应对压力波动。

3. 安装位置

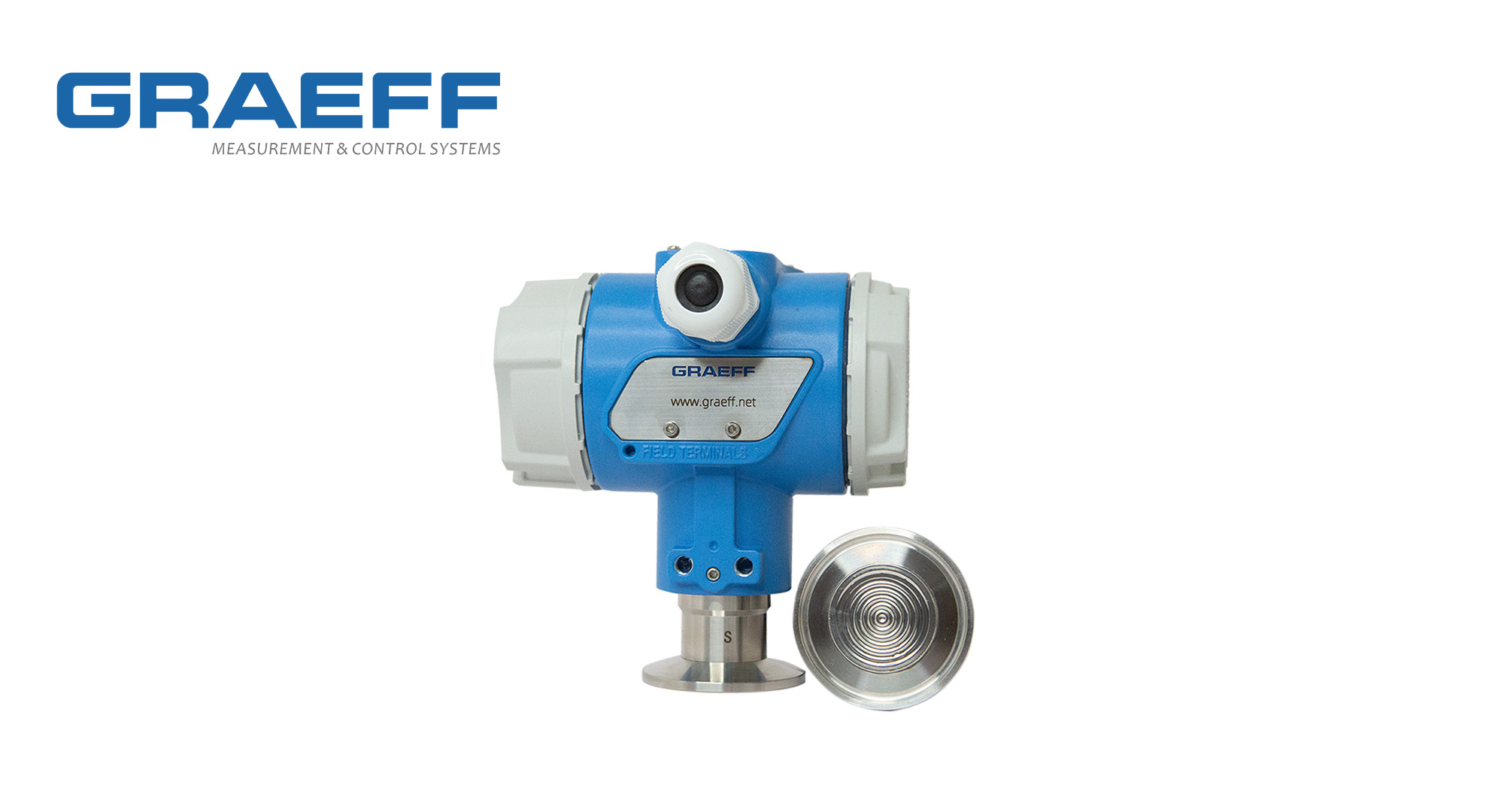

对于粉尘、易结垢或卫生要求高的场合,GRAEFF(格拉夫)提供平膜片设计或卫生型接头,便于清洁和维护。例如,在食品加工和制药行业,其卫生级变送器能够有效防止介质残留,满足严格的卫生标准。

The industrial site environment is complex and changeable, and the selection of the transmitter should fully consider the environmental factors to ensure the reliability and stability of the equipment.

1. Temperature range

In addition to the temperature of the measured medium, the influence of the ambient temperature on the transmitter can not be ignored. The GRAEFF transmitter has a wide operating temperature range and is equipped with temperature compensation to ensure high accuracy in extreme temperature conditions.

2. Pressure range

According to the actual working conditions, it is very important to choose the right range transmitter. GRAEFF offers a full range of transmitters from low to high pressure, ensuring that the equipment range covers the actual measured pressure range, with a margin to cope with pressure fluctuations.

3. Installation position

Where dust, fouling or hygiene requirements are high, GRAEFF offers flat diaphragm designs or sanitary joints for easy cleaning and maintenance. For example, in the food processing and pharmaceutical industries, its sanitary transmitters can effectively prevent media residues and meet strict hygiene standards. driving comfort.

三、精度要求

3.precision requirements

不同的工业场景对变送器的精度要求各异,GRAEFF(格拉夫)提供从高精度到经济型的多样化产品,满足各类需求。

1. 高精度测量

在实验室、制药或精密工业控制场合,对测量精度要求极高。GRAEFF(格拉夫)的高精度变送器采用先进的传感技术和精密制造工艺,精度可达±0.1%,为高端工业应用提供可靠保障。

2. 动态压力测量

对于快速变化的压力信号,如液压系统或动态监测场景,变送器的响应速度和抗疲劳性能至关重要。GRAEFF(格拉夫)的动态压力变送器采用薄膜片设计,能够快速响应压力变化,确保动态测量的准确性。

Different industrial scenarios have different precision requirements for transmitters, and GRAEFF offers a wide range of products, from high precision to economical, to meet all types of needs.

1. High precision measurement

In laboratory, pharmaceutical or precision industrial control applications, the measurement accuracy is very high. Using advanced sensing technology and precision manufacturing processes, GRAEFF's high-precision transmitters offer accuracy up to ±0.1%, providing a reliable guarantee for high-end industrial applications.

2. Dynamic pressure measurement

For rapidly changing pressure signals, such as hydraulic systems or dynamic monitoring scenarios, the speed of response and fatigue resistance of the transmitter are critical. Dynamic pressure transmitters from GRAEFF are thin-film designed to respond quickly to pressure changes and ensure accurate dynamic measurements.

四、膜片材质选择

4.diaphragm material selection

膜片材质是变送器选型中的关键因素,它直接影响设备的耐用性、测量精度和使用寿命。GRAEFF(格拉夫)变送器提供多种高性能膜片材料,以满足不同工况的需求,同时兼顾成本效益。

1. 陶瓷膜片

以其卓越的耐腐蚀性著称,特别适用于强酸强碱等极端腐蚀性介质。它几乎能抵御所有化学侵蚀,是化工领域理想的材料选择。然而,陶瓷膜片的机械强度相对较低,更适合静态或低冲击的测量环境。

2. 钛合金膜片

化学稳定性优异,能够适应多种复杂介质,包括海水、氯化物溶液等。它几乎对所有类型的腐蚀都有很强的抵抗力,但需避免在氢氟酸或强碱环境中使用。钛合金膜片是追求高可靠性和长寿命的理想选择。

3.316L不锈钢

这种材料通用性强,耐腐蚀性和机械强度均衡,适用于大多数工业应用。它成本较低,是性价比极高的选择,尤其适合对腐蚀性要求不高但需要可靠性能的场合。

3. 哈氏合金

以其卓越的耐腐蚀性而闻名,特别适用于磷酸、硫酸等强酸性介质。它能在极端化学环境中保持稳定,但需注意在高浓度硝酸或硫酸中可能会出现腐蚀风险。哈氏合金膜片是酸性环境中的强者。

Diaphragm material is a key factor in transmitter selection, which directly affects the durability, measurement accuracy and service life of the equipment. The GRAEFF transmitter offers a wide range of high performance diaphragm materials to meet the needs of different operating conditions while being cost effective.

1. Ceramic diaphragm

Known for its excellent corrosion resistance, it is especially suitable for extreme corrosive media such as strong acid and alkali. It resists almost all chemical attacks and is an ideal material choice for the chemical industry. However, the mechanical strength of ceramic diaphragms is relatively low and is more suitable for static or low-impact measurement environments.

2. Titanium alloy diaphragm

Excellent chemical stability, can adapt to a variety of complex media, including seawater, chloride solution, etc. It is highly resistant to almost all types of corrosion, but it should be avoided in hydrofluoric acid or strong alkali environments. Titanium alloy diaphragm is the ideal choice for high reliability and long life.

3.316L stainless steel

This material is versatile, corrosion resistant and mechanical strength balanced, suitable for most industrial applications. It has a low cost and is a very cost-effective choice, especially suitable for situations where corrosive requirements are not high but reliable performance is required.

3. Hastelloy alloy

Known for its excellent corrosion resistance, it is especially suitable for strong acidic media such as phosphoric acid and sulfuric acid. It is stable in extreme chemical environments, but it is important to note that corrosion risks may occur in high concentrations of nitric or sulfuric acid. Hastelloy film is strong in acidic environment.

五、安装与维护

5. Installation and maintenance

变送器的安装与维护便利性直接影响设备的运行效率和维护成本。

1. 易安装设计

GRAEFF(格拉夫)变送器采用标准化接口和模块化设计,安装过程简便快捷。例如,其法兰式变送器可直接与管道连接,无需复杂装配。

2. 模块化设计

在需要频繁维护的场合,如石油化工领域,模块化设计的变送器可显著降低维护时间和成本。核心部件可快速更换,减少设备停机时间。

3. 智能诊断功能

部分高端变送器配备智能诊断功能,可实时监测设备状态,提前预警故障,便于及时维护,减少停机时间。

The installation and maintenance convenience of the transmitter directly affect the operating efficiency and maintenance cost of the equipment.

1. Easy installation design

The GRAEFF transmitter has a standardized interface and modular design for easy and quick installation. For example, its flanged transmitters can be connected directly to the pipe without complicated assembly.

2. Modular design

In applications that require frequent maintenance, such as in the petrochemical industry, modular transmitters can significantly reduce maintenance time and costs. Core components can be replaced quickly, reducing equipment downtime.

3. Intelligent diagnosis function

Some high-end transmitters are equipped with intelligent diagnostic functions, which can monitor equipment status in real time, warn of faults in advance, facilitate timely maintenance, and reduce downtime.

六、特殊应用场合的解决方案

6. Solutions for special applications

在一些特殊工业场景中,对变送器的性能和安全性提出了更高要求。GRAEFF(格拉夫)凭借其强大的研发实力,为这些场景提供定制化解决方案。

1. 防爆与本质安全

在石油化工、天然气等易燃易爆环境中,GRAEFF(格拉夫)的防爆型变送器符合国际防爆标准(如ATEX或IECEx认证),确保设备在危险环境中的安全运行。

2. 卫生级设计

在食品、制药行业,GRAEFF(格拉夫)的卫生级变送器采用316L不锈钢材质和无菌设计,符合FDA卫生标准,防止污染,保障产品质量。

3. 极端环境适应性

在深海、极寒或强辐射等极端环境中,GRAEFF(格拉夫)的变送器经过特殊设计和材料选择,能够承受高压、低温或高辐射,满足特殊工业需求。

In some special industrial scenarios, higher requirements are put forward for the performance and safety of the transmitter. With its strong R&D capabilities, GRAEFF offers customized solutions for these scenarios.

1. Explosion protection and intrinsic safety

In flammable and explosive environments such as petrochemicals and natural gas, GRAEFF's explosion-proof transmitters comply with international explosion-proof standards (such as ATEX or IECEx certification), ensuring the safe operation of equipment in hazardous environments.

2. Hygienic design

In the food and pharmaceutical industries, GRAEFF's sanitary transmitters are made of 316L stainless steel and aseptic design, which comply with FDA hygiene standards, prevent contamination and guarantee product quality.

3. Adaptability to extreme environments

In extreme environments such as deep sea, extreme cold or intense radiation, GRAEFF's transmitters are specially designed and materials selected to withstand high pressure, low temperature or high radiation to meet special industrial requirements.

七、综合成本评估

7. Comprehensive cost assessment

在选择变送器时,企业往往容易忽视综合成本评估的重要性。虽然初始采购成本是重要的考虑因素,但长期运行中的维护费用、设备寿命以及因故障导致的停机损失才是影响企业经济效益的关键。GRAEFF(格拉夫)变送器通过高性能材料和模块化设计,不仅延长了设备使用寿命,还降低了维护难度和频率,减少了因设备故障导致的停机时间。例如,采用耐腐蚀材料的变送器虽然初始投资较高,但在强腐蚀环境中能够稳定运行多年,显著降低了因设备损坏导致的维护成本和生产损失。因此,企业在选型时应综合考虑设备的初始成本、运行成本和长期效益,选择高性能、高可靠性的变送器,以实现成本优化和生产效率提升。选择GRAEFF(格拉夫),不仅能获得高质量的产品,更能为企业带来长期的经济效益。

When choosing a transmitter, companies often overlook the importance of comprehensive cost assessment. While initial procurement costs are an important consideration, maintenance costs in long-term operation, equipment life, and downtime lost due to failure are the key factors affecting business economics. Through high-performance materials and modular design, GRAEFF transmitters not only extend the service life of the equipment, but also reduce the difficulty and frequency of maintenance, reducing downtime due to equipment failure. For example, transmitters using corrosion-resistant materials, despite a high initial investment, can operate stably in highly corrosive environments for many years, significantly reducing maintenance costs and production losses due to equipment damage. Therefore, enterprises should comprehensively consider the initial cost, operating cost and long-term benefits of the equipment when selecting a transmitter, and choose a transmitter with high performance and high reliability to achieve cost optimization and production efficiency. By choosing GRAEFF, you can not only obtain high-quality products, but also bring long-term economic benefits to the enterprise.

八、总结

8. Summary

GRAEFF(格拉夫)变送器的选型是一项系统性工程,需要综合考虑被测介质特性、工况环境、精度要求、安装维护需求以及特殊应用场合的具体要求。通过合理选择膜片材质、结构类型和相关参数,不仅能提升测量精度和稳定性,还能有效延长设备使用寿命,为工业生产的高效运行提供坚实保障。选择GRAEFF(格拉夫),就是选择专业、可靠与创新,让我们携手助力您的工业智能化升级!

The selection of the GRAEFF transmitter is a systematic project, which needs to consider the characteristics of the tested medium, the working environment, the accuracy requirements, the installation and maintenance requirements and the specific requirements of special applications. Through the reasonable selection of diaphragm material, structure type and related parameters, not only can improve the measurement accuracy and stability, but also effectively extend the service life of the equipment, providing a solid guarantee for the efficient operation of industrial production. Choose GRAEFF, is to choose professional, reliable and innovative, let us work together to help your industrial intelligent upgrade!