在工业制造的浩瀚海洋中,“力”是驱动一切的核心要素。从化纤纺丝的精密压力到高温熔体的澎湃能量,力的精准测量直接决定了生产质量与效率。作为全球传感器技术的领军者,GRAEFF(格拉夫)深耕压力与温度测量领域,以数字化、智能化、环保化的创新理念,为工业客户提供高精度、高可靠性的解决方案。今天,让我们一同揭开GRAEFF(格拉夫)传感器在“力”的测量中的技术奥秘!

In the vast ocean of industrial manufacturing, "force" is the core element that drives everything. From the precise pressure of chemical fiber spinning to the surging energy of high-temperature melt, the precise measurement of force directly determines the quality and efficiency of production. As a global leader in sensor technology, GRAEFF is deeply engaged in the field of pressure and temperature measurement, providing industrial customers with high-precision and high-reliability solutions with digital, intelligent and environmentally friendly innovation concepts. Today, let's uncover the technical mystery of GRAEFF sensor in the measurement of "force"!

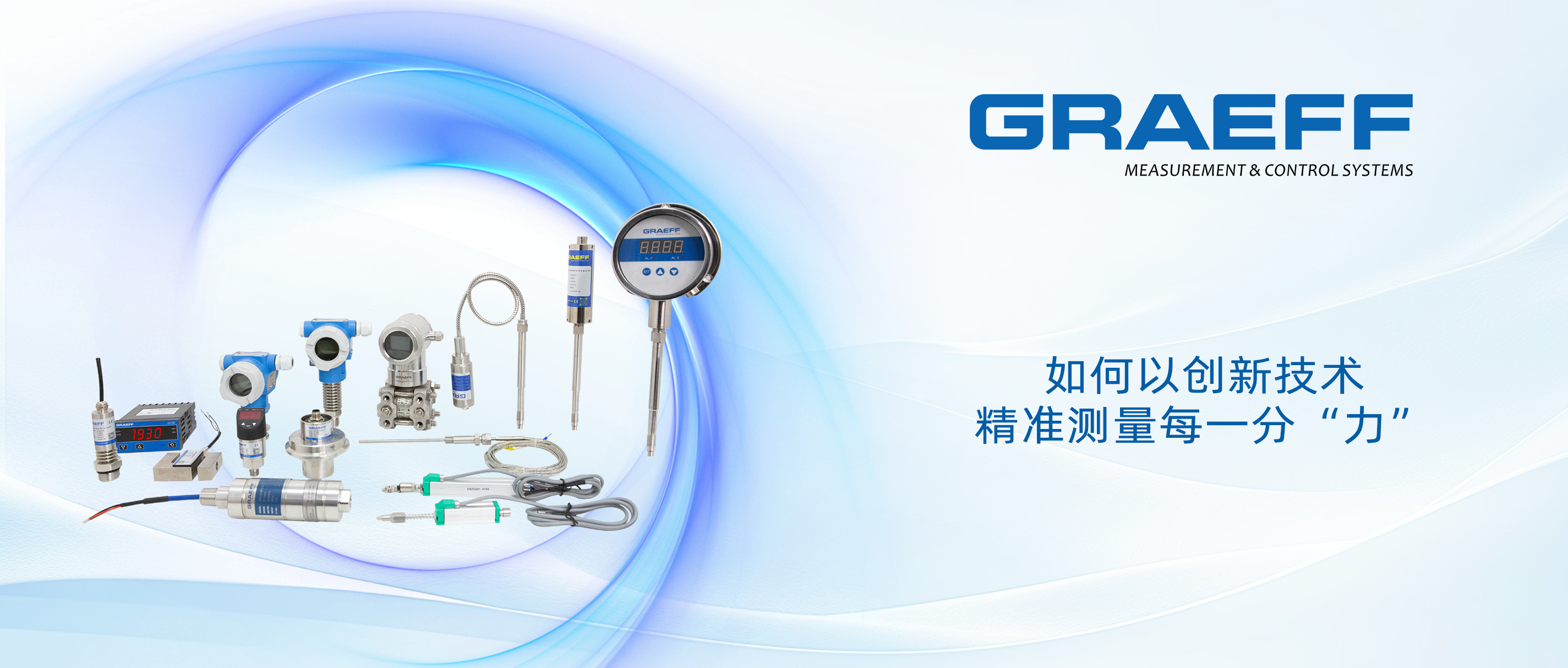

GRAEFF(格拉夫)是一家专注于压力传感器、熔体压力传感器、压力表、温度传感器、工业传感器、智能传感器、流量传感器、位移传感器、液位传感器、压力温度控制仪表、加热器、智能设备、压力与温度校验系统、物联网以及自动化控制系统研发、生产和销售的英国跨国公司。

GRAEFF is a British multinational corporation specializing in the research and development, production, and sales of pressure sensors, melt pressure sensors, temperature sensors, industrial sensors, intelligent sensors, flow sensors, intelligent sensors, displacement sensors, liquid level sensors, pressure and temperature control instruments, pressure gauges, heaters, laser technology, pressure and temperature calibration systems, the Internet of Things, and automation control systems.

工业测量的核心挑战

在工业生产中,力的表现形式多样,而压力作为单位面积上的作用力,是关键的监测对象。例如,在化纤纺丝过程中,熔体压力直接影响纤维成型的均匀性;在石油化工领域,管道压力波动可能引发安全隐患。GRAEFF(格拉夫)传感器通过以下技术突破,将“无形之力”转化为精准数据:

In industrial production, there are many forms of force, and pressure, as the force per unit area, is the key monitoring object. For example, in the spinning process of chemical fiber, melt pressure directly affects the uniformity of fiber forming; In the petrochemical industry, pipeline pressure fluctuations may cause safety hazards. GRAEFF sensors transform "invisible force" into accurate data through the following technological breakthroughs:

1. 高温耐受性:GRAEFF(格拉夫)熔体压力传感器采用不锈钢主体与钛合金涂层,耐高温可达540°C,即使在化纤生产线的高温熔体环境中,仍能稳定工作。

1. High temperature resistance: GRAEFF melt pressure sensor adopts stainless steel body and titanium alloy coating, high temperature resistance up to 540°C, even in the chemical fiber production line of high temperature melt environment, still can work stably.

2. 环保材料创新:摒弃传统汞填充介质,采用环保合金材料,减少温度漂移,确保测量稳定性,同时满足食品、制药行业的严苛卫生标准。

2. Environmentally friendly material innovation: Abandon the traditional mercury filling medium and adopt environmentally friendly alloy materials to reduce temperature drift, ensure measurement stability, and meet the stringent hygiene standards of the food and pharmaceutical industries.

3. 智能化集成:传感器与PLC、DCS系统无缝连接,实时反馈数据至控制中心,实现工艺参数的动态调整,提升生产自动化水平。

3. Intelligent integration: Sensor and PLC, DCS system seamless connection, real-time feedback data to the control center, to achieve dynamic adjustment of process parameters, improve the level of production automation.

多维度赋能工业场景

1. 熔体压力监测:化纤生产的“守护者”

在化纤纺丝系统中,GRAEFF(格拉夫)传感器的安装覆盖熔体过滤器、增压泵、螺杆、纺丝箱体等关键节点。通过实时监控压力变化,可优化熔体流动性,避免设备过载,延长使用寿命。例如,GRAEFF(格拉夫)高温熔体压力变送器凭借0.5%FSO的高精度,成为涤纶、锦纶生产的标配。

1. Melt pressure monitoring: the "guardian" of chemical fiber production

In chemical fiber spinning systems, the installation of GRAEFF sensors covers melt filters, booster pumps, screws, spinning boxes and other key nodes. By monitoring pressure changes in real time, melt flow can be optimized, equipment overload can be avoided and service life can be extended. For example, GRAEFF high temperature melt pressure transmitters with high accuracy of 0.5%FSO have become standard in the production of polyester and nylon.

2. 动态力测量:应变与压电技术的融合

除静态压力外,GRAEFF(格拉夫)结合应变式与压电式原理,开发适用于动态力测量的解决方案:

(1)应变式传感器:基于材料形变引起的电阻变化,适用于长期静态负载监测,如重型机械的承重分析。

(2)压电式传感器:利用晶体电荷响应快速变化的力,专为注塑机、冲压设备等高动态场景设计,响应时间低至微秒级。

2. Dynamic force measurement: Fusion of strain and piezoelectric technology

In addition to static pressures, GRAEFF combines strain and piezoelectric principles to develop solutions for dynamic force measurement:

(1) Strain sensor: based on the resistance change caused by material deformation, it is suitable for long-term static load monitoring, such as the load-bearing analysis of heavy machinery.

(2) Piezoelectric sensor: The use of crystal charge to respond to rapidly changing forces, specially designed for injection molding machines, stamping equipment and other high dynamic scenes, response time as low as microseconds.

3. 数字化与物联网:开启智慧工厂新篇章

GRAEFF(格拉夫)将传感器接入物联网平台,实现远程监控与预测性维护。例如,在石油管道中,多节点压力数据通过云端分析,可提前预警泄漏风险,减少停机损失。

3. Digitalization and Internet of Things: Open a new chapter of smart factory

GRAEFF connects sensors to an iot platform for remote monitoring and predictive maintenance. For example, in oil pipelines, multi-node pressure data can be analyzed through the cloud to provide early warning of leakage risks and reduce downtime losses.

从高温熔体的澎湃之力,到精密仪器的微妙反馈,GRAEFF(格拉夫)始终以技术创新为引擎,为工业客户提供值得信赖的测量方案。未来,我们期待与更多伙伴携手,以“感知之力”推动智能制造迈向新高度!

From the surging power of high-temperature melt to the subtle feedback of precision instruments, GRAEFF has always been driven by technological innovation to provide reliable measurement solutions for industrial customers. In the future, we look forward to working with more partners to promote intelligent manufacturing to a new height with the "power of perception"!